Process Safety and Engineering

Process Safety and Engineering Services

By working closely with our process R&D and plant teams, Pharmaron’s process safety experts offer comprehensive safety research, testing and evaluation services in accordance with global regulatory requirements.

We develop robust chemical reactions and processes to ensure safe scale-up and manufacturing of preclinical and clinical supplies, in addition to expert data analysis to help identify potential weak points in chemical reactions and processes.

Capabilities

Process Safety Capabilities

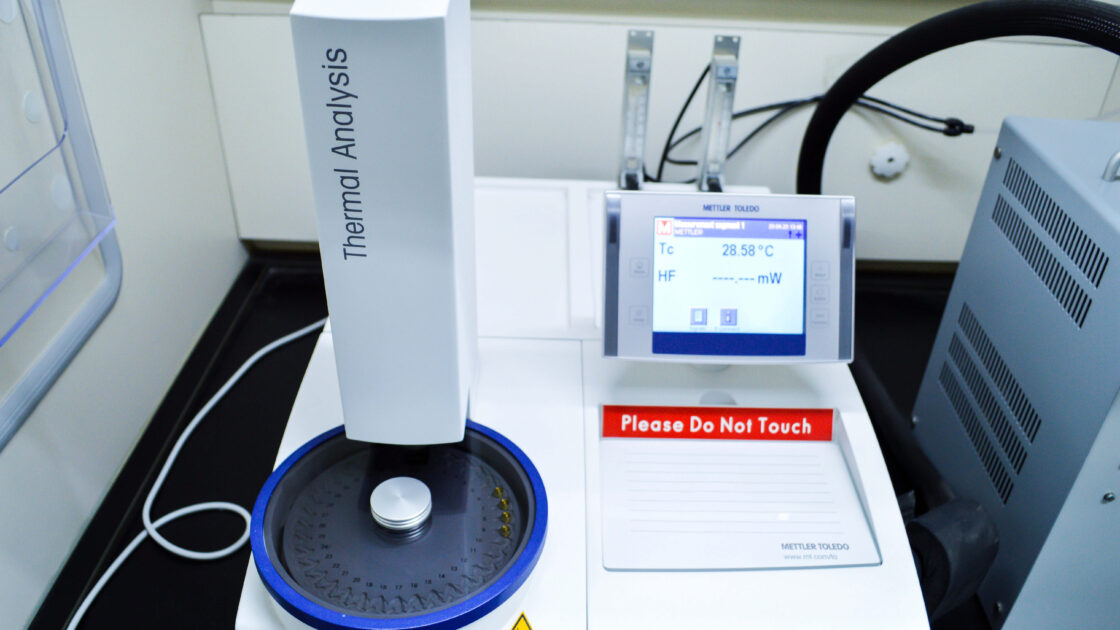

- Chemical reaction hazard testing, identification and mitigation

- Explosive property identification and dangerous goods classification

- Engineering simulations, such as mixing and heat transfer

- Vent sizing calculation to meet engineering requirements and to prevent potential explosion

- Operational hazard evaluation including flammability & static electricity/dust explosion

- Compatibility of materials evaluation with corrosion testing

- Hazard and operability studies and documentation for process scale-up

Process Engineering Services

- Process design, optimization, and validation following the Quality by Design (QbD) approach

- Reaction engineering studies for process understanding, using kinetics / mass & heat transfer studies followed by reactor design, modelling and scale-up

- Application of process analytical technology for mechanistic studies and in-situ monitoring

- Continuous processing (PFR and CSTR) for better safety, stability, cycle time and throughput

- Work-up unit operations: liquid-liquid dispersion, extraction, phase separation, distillation, solvent swap, crystallization, filtration, drying scale-up studies

- Process excellence using engineering optimization and new technologies

- Process simulation and modelling for scale-up

- Process engineering troubleshooting