Process Chemistry

Process Chemistry Services

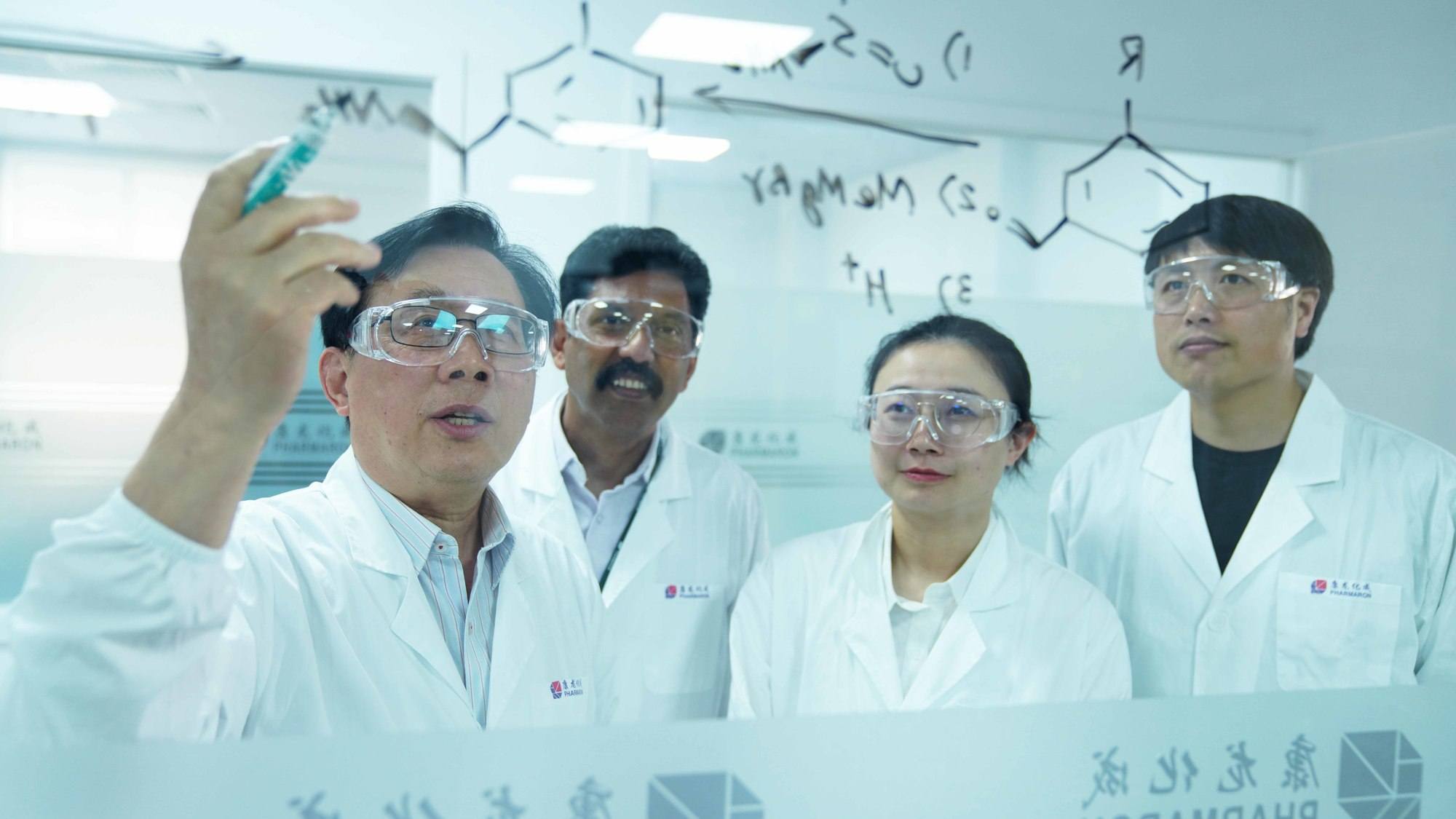

During API chemical development, there are three words that every partner is focused on: quality, speed and cost. Although chemical reactions may work perfectly on lab scale, moving from milligrams to kilograms or tons is not a simple, linear process. Working as an extension of your team, Pharmaron’s process R&D experts can help you develop scalable, safe, robust, cost-effective and ‘green’ processes for the manufacture of your preclinical, clinical and commercial API supplies. We have experience with a wide range of services for API development from lead optimization to IND through to NDA filings. We perform route scouting, design, optimization and process safety studies to deliver high-quality preclinical, clinical and commercial API supplies efficiently and on time.

Learn more: Enabling Technology

Capabilities

Process Chemistry R&D Capabilities

- New route design/existing route redesign for both clinical and commercial supply

- Integrated crystallization design, salt screening and polymorph studies (Material Science)

- Compound purification and isolation improvements

- Fit-for-purpose optimization of chemical reactions

- Cost-effective, safe, sustainable process design & optimization

- Process safety assessment and control

Process Chemistry R&D Capabilities

- High throughput experimentation for optimization of reactions using enzymatic and new catalyst systems development and safety control using flow chemistry

- Application of DoE and modeling tools to inform on process design

- Process validation for late-stage clinical APIs and for registration batches going into regulatory submission

- Scale-up for preclinical/early-phase clinical studies

- Commercial production of intermediates and APIs

China-UK-US Hybrid Model

- Hybrid model leverages our teams in China, US and the UK

- Provides integrated process development and manufacturing capabilities to rapidly accelerate API development

- Lean, efficient and fast problem-solving

- Flexible, cost-effective solutions tailored to your project needs

- Systematic and dynamic knowledge transfer

- Integrated project management including all logistical aspects

Achieving the Chemistry Trifecta

Learn how Pharmaron implements efficiency, safety and sustainability across chemistry projects.